It rained fairly heavily for much of the night. It cleared up a bit for the sunrise, but then started raining again (with the sun still out). Breakfast was a wonderful medley of flavors... muesli, yogurt, fruit, croissants, green tea, orange juice, toast and marmalade.

Sunset from my bedroom window

A delicious spread

The rain showers continued, so instead of going for a walk as originally planned, it seemed like the Speight's Brewery tour would be a better weather choice. So Judy called to sign me up for a 10 am tour. Brian had a dentist appointment around that time so he could drop me off. The tour was to last 1 1/2 hours, but he was fine with picking me up as well.

A charming building on the way to town

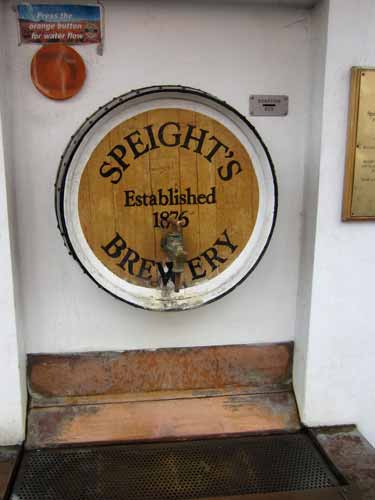

When we arrived at the brewery, Brian pointed out the large tap coming right out of the wall outside. This was a place where people could bring their containers and get free water directly from the brewery's own spring deep under the ground. There was a constant flow of people to it.

The brewery used to be connected to another building across the road by the walkway.

The free water tap

I was the first to arrive for the tour. The two guys at the desk were quite jovial and had fun with my name... including what nicknames they could come up with since my name was so long. In the end, I managed to keep my full name AND they gave me a discount (only charging me $20 instead of $25). Originally it was supposed to be a rather large group, but a busload of 12 people called last minute to cancel, saying the bus had broken down and they would make it at 2 pm instead. So it was just Graham (the tour guide), me, and a couple from Australia with their 8-year-old daughter.

We began with an exhibit in the next room which demonstrated the trade of the cooper, or barrel maker. The coopers worked in pairs and were required to produce so many barrels per week (depending on the sizes of the barrels). It was much harder to make a barrel to hold liquids than dry goods. First the boards were cut and shaped. Special tools were used to give each board a slight curve. These were then assembled together and placed under a steam cone. Next metal rings that held the barrel together had to be made and put on. These had to be tight enough to make the barrel waterproof. Gaps could be filled in with native flax to create a perfect seal.

The wooden cask was how beer was stored and transported until the 1950's when metal casks and beer tankers were introduced. That basically spelled the end of the cooper.

Shaping the boards. One tool was used to curve the outside of the board, and another was used to hollow out the inside.

A flat board (top) and a finished curved board

The steam cone

Graham demonstrates how the metal would be curved to shape.

Putting together all the pieces

Giant bales of flax

Various barrel sizes

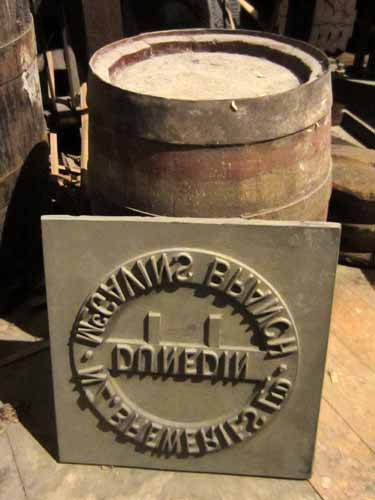

An impressive brand

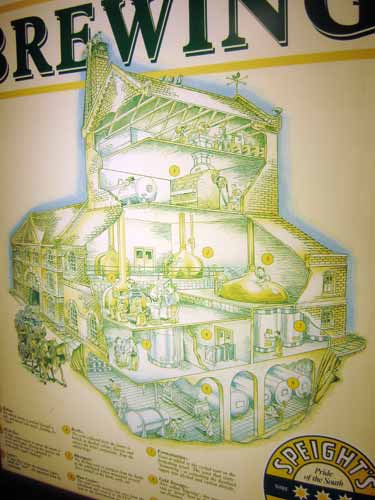

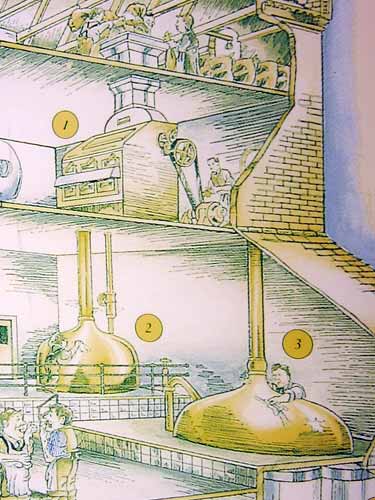

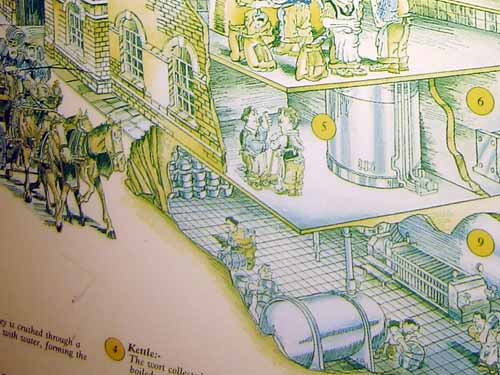

We took an elevator to the top floor of the brewery. This was a "flow-down" brewery, meaning the ingredients were brought to the top level and then flowed their way down to the different floors as they were processed... so grain storage, to milling, to mashing (cooking), to cooling and filtering, to fermenting and storing, and finally shipping. It was joked that each floor had its own bar... so that way the men were always easy to find when they were on break instead of having to try to track them down at the local pub!

The flow-down brewery

Stored grain could be dumped into the milling machines which then dropped down to the kettles...

...then down to cooling and filtering, and finally to fermenting, storing (lagering) and shipping.

We first walked through several rooms detailing the history of beer... from its first conceptions as a damp bread up through the founding of Speight's.

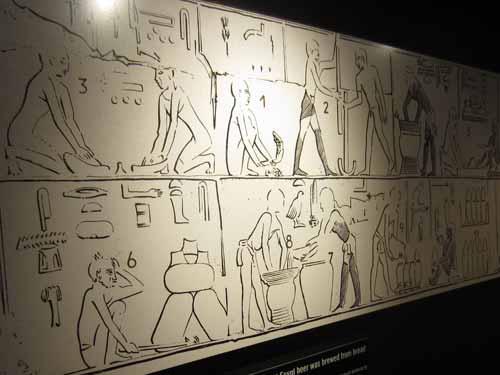

The oldest inscribed clay tablet, which dates back to 6000 B.C., depicts the brewing of beer for sacrificial purposes. By 4000 B.C., the Babylonians had 16 different kinds of beer.

Showing how the ancient Egyptians used to make bread as well as beer

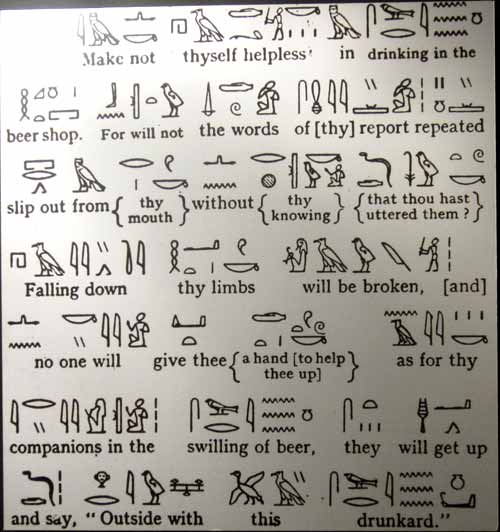

The more things change, the more they stay the same!

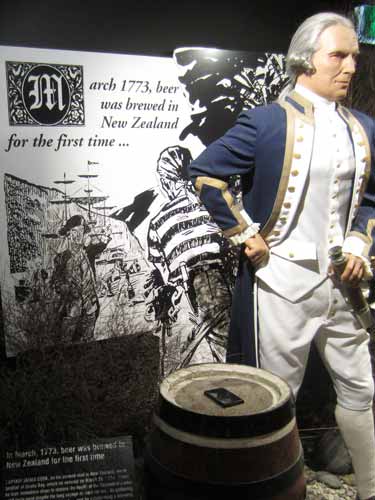

We then moved on to beer in Europe... and finally New Zealand.

Drinking out of the skull of your enemy would give you his strength and power.

Captain Cook's "Spruce Beer" was made using manuka and rimu (which he thought was spruce) foliage. It wasn't very tasty but was valuable for the anti-scurvy elements which it contained.

Speight's brewery was founded in 1876, when three employees from another Dunedin brewery quit their jobs and went into business for themselves.

As early as the 1880's, the brewery was winning international awards.

Hugh Speight (pronounced 'Spayt') was the grandson of James Speight, one of the three founders. He became director in 1928 after the death of his father, Charles. In 1936, he oversaw the construction of the new brewery. He died in 1969 at the age of 64.

Hugh Speight

The first employees of the new brewery in 1940

Much of the building was under construction (it was being reinforced to meet earthquake safety standards) so it was often rather loud in places and several areas were closed off with large fencing and tarps. Workmen frequently passed us carrying large loads of debris or building materials. Graham mentioned it was a concern that at some point the brewery might no longer be able to give tours since the building is not wheelchair accessible, and if one person complains... that's it for everybody.

There wasn't much currently in the top floor that we could visit... just a few bags of grain and some sample ingredients. We headed down the stairs to the milling room.

The hops come from the Nelson district (on the north part of the south island). Cane sugar is used to supply additional fermentable matter.

Hmmm... is it worse to have to get a bag from the top or from the bottom of the pile??

A batch of malt that is to be brewed is weighed and then poured into the bin. Magnets remove metal fragments and screens remove stones and any other contaminants. When it is time to brew, the malt is crushed by rollers as it passes through the malt mill. Screens then separate the malt husk from the crushed malt flour.

Anti-explosion shelves?? Apparently the resulting dust can spontaneously combust. The mills are always braced against an exterior wall, just in case.

A glimpse at some of the earthquake reinforcement. This will eventually be covered with plaster.

We next got to walk across the small bridge over the road that used to go to the other building which used to be the bottling house. It was lined with historical photos.

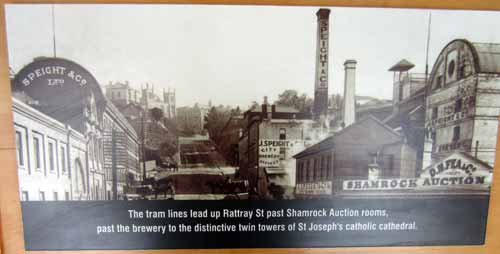

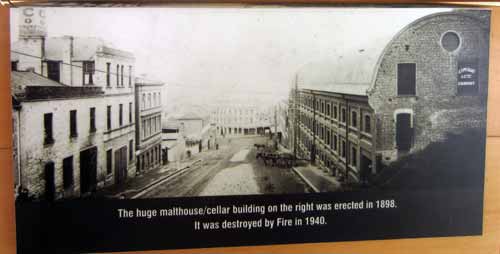

The street then...

... and now (if you look closely behind the trees on the left, you can still see the tips of the twin towers)

A building that was built in the 1940's was being torn down to reveal the facade of the original one. The plan is to reconstruct an original garden in front as well.

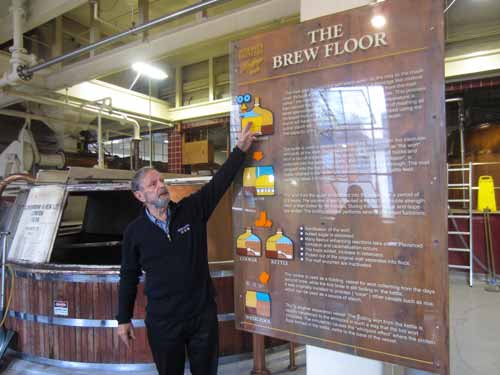

We then went into the heart of the brewery... the room with all the big, shiny copper kettles. Each one had a different function: the mash-tun was where the mash (the crushed malted barley and water) is stirred and heated, which converts the malt starch to fermentable sugars; the lauter where the dissolved sugars (now called the wort) are separated from the malt husks; and finally the kettle where wort is boiled and the hops are added. The mixture is then pumped downstairs where it goes through the whirlpool (to remove unwanted proteins) and then cooled and the yeast is added.

Graham is standing in front of a mash-tun from 1936. Unfortunately, while it still functions perfectly, new technology is much more efficient and it is going to be replaced soon.

A peek inside while it was working

And finally, we got to the best part of the tour... the tasting! We got to sample five different beers (and one cider). Since we were such a small group, Graham let us tap our own beers. He said normally (and especially when the cruise ships come in with such large groups) it really is too chaotic to be possible.

The beers were quite cold but no overly hopped.

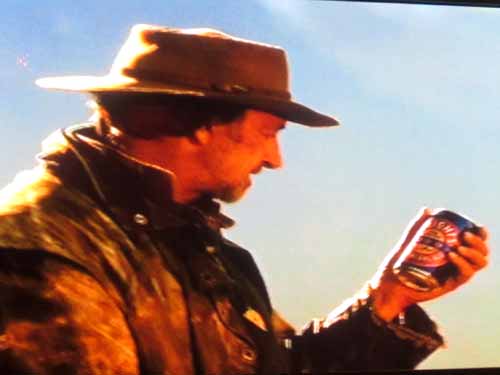

While we sampled, we got to watch the series of "The Southern Man" commercials. These were great! The basic theme was the adventures of an old New Zealand cowboy (who loved his Speight beer) and his younger sidekick.

Frank Whitten had been doing them since 1992 but passed away in 2011.

Watch "Better Half"

This ad was in celebration of their 125th year

Watch "Happy birthday to... ewe"

(There are lots more commercials posted on youtube but the quality isn't very good.)

Good on ya, mate!