CALDWELL (Day 6 - part 6)

As we set out again, it was obvious a big storm was blowing in.

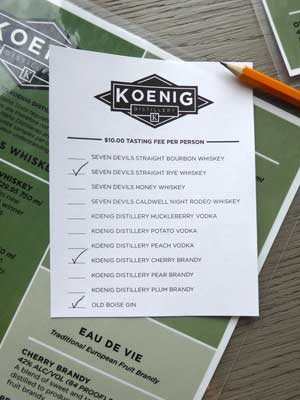

Koenig Distillery, established in 1999, was our final stop of the day. The winery and the distillery both belong to the same family. Brothers Greg and Andrew started them together in one building that the two designed and built. As both businesses grew, the space became too small. So in 2009, Greg moved his winery a few miles away.

A hand-crafted copper still from Germany

Selecting our three choices each

We had a splash of straight rye whiskey, gin, huckleberry vodka as well as cherry, pear and plum brandies.

We then got to explore the distilling equipment and barrel house.

Smaller stills were used for fruit brandies, while the larger ones were for whiskey and vodka. Copper is the catalyst for alcohol distillation which produces the highest quality spirits.

The barrel house can hold 3,168 barrels. They are aged 4 -6 years before being bottled. The aging process intensifies the colors and allows the whiskey to mellow. Each one is handmade in a cooperage in Louisville (Kentucky) from white American oak and can produce roughly 300 bottles. Through evaporation, a barrel loses approximately 13 gallons after 4 years.

The rain hit on the drive back.

And finally... I got to try the candy bar that had haunted the entire day!

The Idaho Spud, made by the Idaho Candy Company (founded in 1901), has been produced since 1918. Its shape is intended to resemble a potato.

A cocoa-flavored marshmallow center is covered with a dark chocolate coating and sprinkled with coconut.

return • continue